SECTION 32: TAILCONE ATTACHMENT: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 1: | Line 1: | ||

== Page 32-4 == | == Page 32-4 == | ||

[[File:32-4 dimple.jpg|300px]] | [[File:32-4 dimple.jpg|300px]] | ||

When to dimple the holes marked in red? Answer: Page 32-5, step 3: Dimple all skins common to the F-1006 A, B & D bulkheads. In this case, it is the F-1006A bulkhead. | When to dimple the holes marked in red? Answer: Page 32-5, step 3: Dimple all skins common to the F-1006 A, B & D bulkheads. In this case, it is the F-1006A bulkhead. | ||

[[File:Tailcone_attachment.jpeg|500px]] | |||

== Hints == | == Hints == | ||

Revision as of 02:43, 29 March 2022

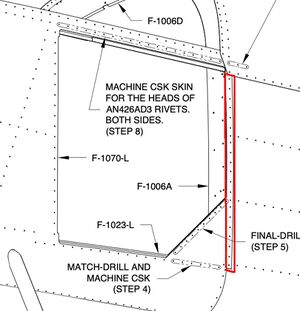

Page 32-4

When to dimple the holes marked in red? Answer: Page 32-5, step 3: Dimple all skins common to the F-1006 A, B & D bulkheads. In this case, it is the F-1006A bulkhead.

Hints

- Stack at floor joint from bottom to top:

- fuse skin (F-1077)

- tailcone skin (F-1078)

- bulkhead (F-1006B)

- rib tabs (e.g. F-1019-R)

- Use plastic wedges to guide the tailcone bottom skin to go above (inside) the fuselage bottom skin, e.g. at Amazon

- Use two thin strips of aluminum (3/4 inch wide) in the bottom corner sections to guide the tabs of the tailcone to go inside the fuselage skin.

- Use an inflated 20 inch truck inner tube underneath the fuselage center to lift the fuselage slightly, allowing a swivel motion within the fuselage cradle constraints e.g. at Amazon

- This is going to be the first section where you will be happy to have a creeper to get underneath the fuselage, e.g. this one at HF.